All About Wool Yarn

Wool yarn has been around for thousands of years. Way back in history, wool yarn was one of the few yarns you could find for any crafty activity. Whether a weaver, knitter, crocheter, or otherwise, you’d turn to the staple of wool for your yarn. It’s likely you’d learn to spin at a young age and progress to knitting or crocheting when you were able.

These days we’re lucky enough to have a HUGE selection of delicious yarns already made for us in an incredible variety of colors, weights, and textures. But have you ever wondered where exactly your wool yarn came from?

Though wool production has come a long, long way, and now we use modern machinery and technology, it’s still quite a process. Let’s take a look into how wool yarn comes to be.

Where Does Wool Yarn Come From?

Wool is a natural and highly valuable fiber that we use in many ways, such as clothing, blankets, and even insulation. But where does it come from?

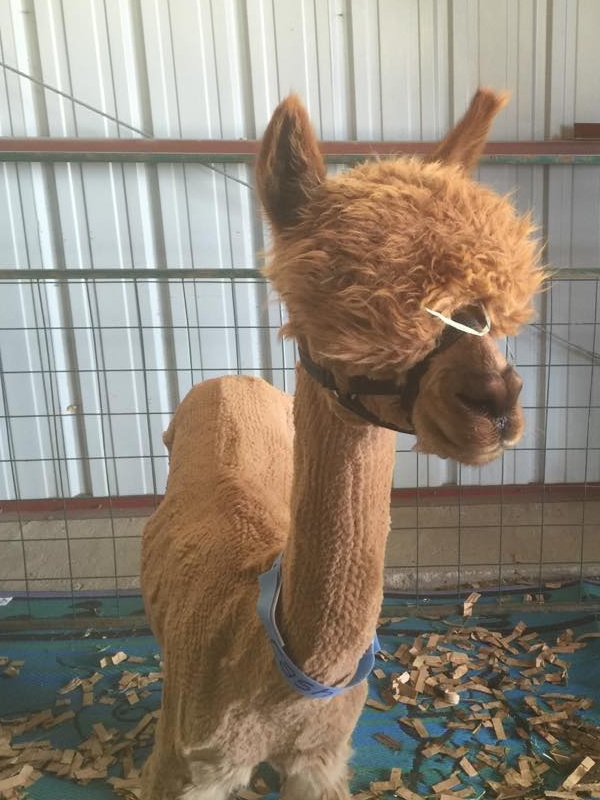

Well, the answer is quite simple: wool comes from animals, specifically sheep, but we also use the hair of goats, llamas, alpacas, and even camels. Sheep, however, are our source of wool. Breeders have selected the best sheep for thousands of years to provide the ideal qualities of wool.

Where Are Sheep Raised?

Sheep are one of the most important livestock animals in the world. Farmers raise sheep for meat, milk, wool, and leather. Man domesticated sheep hundreds of years ago. Sheep are hardy, natural, and versatile. But have you ever wondered where sheep are raised? In many parts of the world, sheep are an essential part of the agricultural industry, providing a source of income and food for millions of people.

Raising sheep is most common in rural areas with large tracts of land available for grazing. The biggest sheep-producing regions of the world are Australia, New Zealand, and the United Kingdom (often in West Yorkshire and the Lake District). In these countries and regions, farmers raise sheep primarily for their wool. Industries use this wool in various products like clothing, carpets, and industrial fibers. The United States also has a significant sheep industry, with sheep farms found in almost all 50 states. In North America, farmers commonly raise sheep for their meat and milk.

People raise sheep in many other parts of the world, from the plains of Africa to the mountains of South America. And sheep need plenty of pasturelands and access to fresh water. With proper care and attention, sheep farming can be a profitable and sustainable way of life, but exactly how does wool get from the animals onto our hooks and needles?

Sheep Shearing

Sheep shearing is the process of removing wool from a sheep’s body. It is a skilled and necessary job carried out in most sheep-rearing countries. It’s most needed especially during the spring and summer months when wool growth is at its peak. Shearing helps prevent the sheep from overheating. Sheep don’t want or need their bulky wool during warmer months. Not so long ago, someone found a sheep that had been wandering in the wild for several years. It was carrying many extra pounds of wool and was growing weak from the weight.

Shearing is a vital process for both the health of the sheep and the production of high-quality wool. Tight and long wool can cause diseases or parasites to take hold, and by removing it, the shearer clears the way for better hygiene and a reduction of wool-based issues. But sheep shearing is not just about wool health and maintenance. Correctly shearing sheep helps farmers turn their wool into valuable products. Clothing, blankets, and rugs are likely the most common. Properly sheared wool can also be sold at higher prices too. Wool-based industries need to produce quality products.

Sheep shearing is a critical yearly process that farmers undertake to maintain their sheep and generate high-quality wool for the market. The shearer’s skill in shearing ensures that the sheep are well-kept and that the wool is of prime quality. So, the next time you see a herd of sheep, remember that shearing them is a vital process that protects their health and ensures the production of valuable wool, which processors and spinners kindly make into yarn for us avid crocheters.

How Wool Is Processed

Raw wool needs washing to remove impurities and any foreign debris. Once washed, it’s sorted, graded, and finally spun into yarn. This process has many steps, and we’re just going to look at some of those steps briefly.

Scouring

Raw wool (or greasy wool) needs washing and scouring to remove dirt and natural oils from the wool fibers. Lanolin gives raw wool its greasy feel. Skincare companies use it in treatments due to its protective properties. It’s naturally very sticky and hard to remove. Washing is a difficult process. Soap or emulsifiers help, but it can be quite a complex process. Let’s just say your wool needs a thorough cleaning before the next step of processing.

They also need to remove vegetable matter, such as hay, grass, or other plant materials. Because we don’t want scratchy spots in our carefully crafted goodies.

Sorting and grading

Sorting and grading wool isn’t as easy as it might seem. There are many different qualities of fiber on one single sheep. They gather fleece from the same parts of different sheep and process it together to keep the quality consistent.

The best quality wool comes from the back and shoulders of the sheep. The worst comes from the lower legs. As you can imagine, thorns, dirt, and other debris cling to those shorter, coarser hairs.

Wool fibers are graded for:

- Color – uniformity

- Crimp – how tight of a wave in each fiber

- Elasticity – how much stretch

- Fineness – thickness of the fiber (in microns)

- Length – from the cut to the tip

- Strength – speaks for itself

Carding and combing

Carding and combing straighten and align all fibers of the same length and quality. These processes help to align all fibers in the same direction in preparation for spinning.

Machines remove any short fibers or knots during the carding and combing processes. Noils and spinners are shorter pieces. Spinning businesses add them to other yarns, such as tweed yarns.

Spinning

Once all fibers align, they narrow the massive sheet of fibers down to roving. Roving has barely any twist. Machines wind it into tops (like huge extra-thick balls of yarn). People place the tops onto large spinning machines and join them in as needed to produce yarn. From balls and skeins to hanks and, more recently, yarn cakes, you’ll find yarn packaged in all shapes and sizes.

No matter how we see it as consumers, the quality of wool varies depending on the breed of sheep. Other contributing factors are climate, nutrition, and age. Wool is highly versatile. You’ll find it in any number of textiles, from high-end fashion pieces to everyday clothing.

So next time you pick up some skeins of wool yarn to make something special or put on a cozy wool sweater or beanie, you can appreciate the origins and production processes of this amazing natural and renewable material.

Best Sheep Breeds For Wool Yarn

Sheep have been an important part of human civilization for thousands of years. The wool industry is still a key sector in many parts of the world. Farmers breed sheep specifically for their high-quality fleece. However, not all sheep breeds are created equal when it comes to wool production. Some breeds produce soft wool, while others produce coarse and durable wool, more commonly used for carpets and rugs. Here are some of the best sheep breeds for wool yarn.

Merino Wool

One of the most popular breeds for wool yarn is the Merino sheep. Originally from Spain, people love Merino yarn for its fine, soft hand. It’s super popular for clothing and blankets. Merino wool is also very elastic so it’s often spun into a very fine yarn. This makes it ideal for a wide range of knitting and crocheting projects. Australia and New Zealand are where you’ll find large numbers of Merino sheep.

Blue-Faced Leicester (BFL)

Another popular breed for wool yarn is the Blue-faced Leicester sheep. This breed has lustrous, long-staple wool that is very soft and has a natural sheen. This wool is particularly popular for hand-dyeing yarn as it takes the dye very well.

Shetland

The breed well-known for its wide range of natural colors and wool that is soft, warm, and durable is Shetland sheep. Shetland wool is particularly popular for creating traditional Fair Isle patterns due to its ability to hold its shape and its natural color variations.

Lopi Wool

Lopi wool is a type of yarn made from the fleece of Icelandic sheep. It’s especially useful for those who live in cold climates. Composed of two types of fibers, Lopi wool has an inner and outer coat. The inner coat is very fine and soft, while the outer coat is coarser and provides insulation.

Wool insulates incredibly well even when it’s wet. That’s why Lopi wool, and wool in general, is so popular. This makes it an ideal choice for outdoor enthusiasts who need clothing that can keep them warm and dry, even in wet conditions. The wool is also hypoallergenic and flame-retardant, making it a safe choice for clothing items.

Lopi wool is available in a wide range of natural colors, from light cream to dark brown. Its unique properties make it a popular choice for making traditional Icelandic sweaters. Other items include hats, gloves, and scarves. With its durability and insulating properties, it’s no wonder that Lopi wool remains a popular choice for clothing makers around the world.

In conclusion, the best sheep breeds for wool yarn are those that produce high-quality, soft, strong, and durable wool. Each breed has its own unique characteristics and advantages, making them popular for different types of yarn projects.

Properties of Wool

One of the most notable properties of wool is its insulation capabilities. Wool fibers naturally trap air and maintain heat, keeping wearers warm and toasty in cold weather. This makes wool especially beneficial in outdoor gear and winter clothing. Did you know wool is naturally fire-resistant? That’s why carpets and rugs are often made of wool. It’s also a durable fiber that is resistant to wear and tear. This means wool clothing and textiles can last longer than other fabrics.

Another remarkable property of wool is its moisture-wicking abilities. Wool fibers have a natural crimp that creates pockets of air, which allows moisture to evaporate from the skin quickly. This makes wool a common choice for athletic wear. It helps to keep the body dry and comfortable even during intense exercise or activity.

Wool is also hypoallergenic and naturally resistant to bacteria and odor, making it an excellent choice for people with sensitive skin. One thing I really love is that even if your wool socks get wet, they still keep your feet nice and warm.

Wool is a unique and valuable natural fiber that is prized for its versatility, sustainability, and amazing properties. Whether you need warmth, durability, moisture-wicking abilities, or hypoallergenic textiles, wool is an excellent choice for clothing, bedding, and other textiles. Its natural benefits make wool both functional and fashionable, making it a staple in the fashion and textile industry.

Why Can Wool Yarn Felt?

Felting makes fibers of a wool material, such as a wool sweater or hat, fuse or mat together. This creates a denser, more compact material. Usually, this happens accidentally in the washing machine where the perfect felting conditions occur naturally.

The requirements for wool felting are moisture, heat, pressure, and friction. But the reason this happens in the first place is that each wool fiber has minute scales.

Keep reading to find out how felting happens.

What Happens When Wool Yarn Felts?

The felting process begins when the fibers of the wool material become moist and warm/hot, either through exposure to water or the natural oils in the skin. Once moist and heated, the scales on the fibers tend to open up and stick out, causing the scales of separate fibers to interlock with one another. This interlocking process speeds up when you apply pressure and heat by rubbing the wool material vigorously. This happens naturally in a washing machine on a hot wash.

As the fibers open up and interlock, they create a dense, compact mat of wool that is highly durable and resistant to wear and tear. Accidental felting tends to happen when people toss a wool sweater in with the rest of their washing load without reading the washing instructions on the label.

This interlocking and pulling together of the fibers often causes wool clothing to shrink several sizes. This is one of the reasons that wool felt bags are so durable. They won’t shrink any more than they already have.

In addition to its durability, felted wool is also insulating, and able to regulate temperature and moisture levels. This makes it ideal for use in a variety of applications, from clothing and home goods to industrial and commercial products. So, because wool felts, that’s one of the key reasons it’s still valued today.

Can Felting Be Reversed?

This is one of the main questions about felted wool. As we’ve learned, felting is the process of matting or binding wool fibers together using heat, moisture, and agitation. It can create beautiful and durable pieces, but it does have its drawbacks. One of the most common questions people ask about felting is whether or not we can reverse felting.

The short answer is no. Once wool fibers felt, a permanent bond exists that cannot be undone. The scales on the outside of the wool fibers interlock and shrink. This causes them to lock into a solid mass. The fibers are no longer separate and they can’t untangle. Attempts to reverse felting by pulling or stretching the fibers may only result in damaging the piece further. However, you can help prevent shrinkage and felting by gentle handling. Cooler washing temperatures, and avoiding rough types of agitation are essential. Wringing can also cause felting.

So, what if you don’t want your wool project to felt? Is there a way to avoid it other than cooler washing? Enter superwash wool.

What Is Superwash Wool Yarn?

Superwash wool is a type of wool treated with a specialized chemical process. This process prevents the natural felting properties of wool. Superwash processing removes scales on the wool fibers that cause felting. This allows the yarn to be machine-washable without the risk of felting or shrinkage. This process also gives the wool a smoother texture, making it more comfortable to wear against the skin.

Superwash wool yarn is popular among knitters and crocheters for its ease of care, versatility, and durability. It’s commonly used for making socks, sweaters, and other clothing items. So, if you’re looking for a wool fiber that is easy-care and can last a long time, superwash wool is an excellent option.

Are Other Animal Fibers Called Wool?

In short, no. Wool usually only applies to the coat of a sheep. Fiber is the common name for other animal coats or fleeces.

There are many more animals who very kindly supply us crocheters and knitters with some gorgeous, fine, and very soft fibers for our crafting pleasure. They include camel, llama, alpaca, vicuna, bison, angora goats (mohair), and angora rabbits. But we’ll talk about those another time.

Check Out Some of Our Favorite Wool Yarns…

Merino wool yarn has to come at the top of the list. It doesn’t matter the weight. Whether you prefer lace weight, worsted, roving, or any weight in between, merino wool is a winner for crochet or hand-knit yarn.

Alla Prima Super Bulky – 52 yards – 120g

Malabrigo Worsted – 210 yards -110g

Malabrigo Arroyo Sport – 335 yards – 100g

Superwash Merino wool also comes at the top of the list. You get the added benefit of being able to machine wash (and sometimes machine dry) this versatile yarn choice. So, yarn weight doesn’t matter as far as quality is concerned. From the heaviest worsted (or thicker) down to the lightest lace weight, you can’t go wrong with superwash Merino.

Some awesome 100% superwash merino wool yarns we love are:

Swish Bulky – 137 yards – 100g

DK Swish – 123 yards – 50g

Swish Worsted – 110 yards – 50g

Twill Worsted – 149 yards – 100g

Twill Fingering – 183 yards – 50g

Swish Bulky – 137 yards – 100g

Muse Aran – 114 yards 100g

…And Some Of Our Favorite Online Yarn Stores

Check out some other yarns you might like…they may or may not contain wool, but…they’re AWESOME!!!